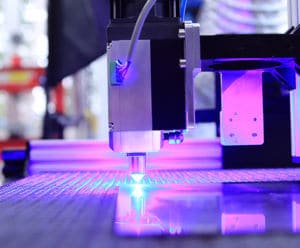

Laser marking, a technology mainly used in the production of consumer goods and industrial applications, is an incredibly versatile and precise customization tool. It is broadly used for branding purposes. From the brand name you see on your pen to the brand logo and slogans you notice on promotional items, all these things are the results of laser marking.

This article seeks to explore the potential transformation that can result from laser marking and how it enhances personalization and customization across different sectors. But, before coming to that, let’s explore the importance of this innovative and precise customization tool.

The Importance of Laser Marking

Laser marking is leading the modern manufacturing and branding trends by transforming product personalization and customization. Unlike other traditional methods like printing, laser marking is more accurate in creating fine designs with better clarity and precision when dealing with any sort of surface. Based on laser beam power, manufacturers are able to get permanent marks on various materials including metals, glass, plastics as well as ceramics hence making each item unique.

This technology comes up with several outstanding advantages ranging from permanent marking, high-quality & readable marking, and high-speed & low-cost marking solutions.

Applications Across Industries

In different industries, where product or brand customization and personalization are key, the flexibility of laser marking finds its way through.

Automotive

Laser marking is highly employed in the automotive field for part identification, serialization, and branding. Engine components to chassis parts, laser-marked codes, and logos not only enable traceability and authentication but also enhance brand visibility as well as aesthetics.

Electronics

The electronics industry extensively uses laser marking to precisely mark components as well as circuit boards for product identification and traceability. This makes it possible for automated production processes to be integrated seamlessly through the use of laser-marked serial numbers, barcodes, or even logos that also aid in quality control and prevention of counterfeits.

Medical Devices

In the medical device industry, surgical instruments like implants among other medical equipment can be permanently marked using a laser engraver. The presence of such laser-marked identifying codes or regulatory information ensures adherence to strict regulatory demands concurrently enhancing the safety of patients while making the product durable.

Jewelry and Fashion Accessories

Laser marking is creatively applied in the jewelry and fashion accessory market, where personalized etchings and elaborate patterns accentuate luxury and exclusivity in high-end items. Among such accessories, conventional ones are turned into precious mementos or statement pieces by laser-marked logos, monograms as well as custom designs.

Laser Marking: Benefits to Businesses

Laser marking has a lot of benefits both to businesses and consumers considering its integration into manufacturing processes:

Better Brand Distinction

Personalized creations differentiate companies in a competitive market hence distinguishing their brands from others while also augmenting loyalty for their firms. The customers or potential consumers can better identify a company, brand, or product with laser-marked graphics and texts.

Increased Value of Product

The value of products can go up through laser-marked personalization which enables businesses to set higher prices for their products, resulting in increased profit margins. Customers are willing to spend more on products that they have had specially made for them.

Improved Product Traceability

Throughout the supply chain, from manufacturing to distribution and beyond, laser-engraved identification codes and serial numbers offer strong product traceability. This ensures accountability, quality control, and regulatory compliance, as well as reducing the risks of counterfeiting and product diversion.

Streamlined Production Processes

No other technology can match laser marking in terms of its efficiency, adaptability, and support for rapid prototyping, on-demand customization, and agile manufacturing. Laser marking helps reduce time-to-market by eliminating the need for traditional tooling and setup which are major cost items in production hence increasing the overall competitiveness of an organization.

Incorporating Personalization and Customization in Laser Marking

Several techniques can be utilized efficiently when using laser marking technology to add personalization and customization features to a product. A few of those are as follows:

Personalized Text

To achieve the ultimate business goal and to establish a relationship with the customers, companies utilize personalized texts through laser marking. It can be used to etch personalized text such as names, dates, or messages onto a number of materials. Personalized text that is marked by lasers adds emotionality to products that act as gifts or mementos.

Graphic Engraving

With laser marking, tiny and detailed graphics, logos, and designs can be engraved on the surface of objects to turn them into rare and unique pieces of art. Laser-marked graphics ranging from corporate branding to decorative embellishments enhance the aesthetics of your products.

Variable Data Printing

By laser marking, various data such as sequential serial numbers, barcodes, or QR codes can be printed on products such as automotive parts or medical devices. This allows for batch tracking, inventory control, and product authentication for compliance with regulatory requirements and industry standards.

Color Marking

Advancement in laser technology now makes it possible to obtain colored marks on selected materials like plastics and ceramics. Creative expression and brand customization now get a boost from this new technique since it provides possibilities for companies that want to make their product more visually appealing or head-turners.

More to Know From Laser Marking Technology

A few more things that you should know about Laser Marking Technology include:

Integration with Digital Platforms

Consumers get a seamless experience when they customize or personalize items through digital integration of e-commerce platforms and laser marking systems. From online design tools to on-demand manufacturing, digital integration makes the entire customization process more efficient across all stages such as design creation and product delivery.

Expansion into New Markets

There is a growing demand for customized and personalized products across different industries, which is why laser marking is expected to enter new markets. The technique can be used in various industries including consumer electronics, consumer packaged goods, etc., therefore adding value and differentiation to products at a relatively lower cost.

Sustainability and Eco-Friendly Solutions

Laser marking systems are evolving to employ eco-friendly substances and actions with a rising emphasis on sustainability and environmental stewardship. From laser marking on reprocessed plastics to bio-dissolvable substrates, manufacturers are trying out inventive ideas for minimizing environmental impacts while enhancing customization as well as personalization properties.

Concluding Remarks

To sum up, there is a paradigm shift in customization and personalization that laser marking represents. It offers businesses an opportunity to create personalized experiences for their customers which no other industry can match. Automotive, fashion, electronics, and jewelry industries among others have had seamless integration of personalization through laser etching which creates differentiation of brands, consumer engagement, and increases overall competitiveness. Looking into the future, therefore, unlimited possibilities remain for laser marking in customization and personalization showing continuing improvements till the point of perfecting personalized products.